|

Vehicle Parameters |

|||

|

Vehicle Model |

CLW5252GYYB5 |

Vehicle Brand |

CLW |

|

Overall Dimensions |

10233*2490*3010mm |

Curb Weight |

9500 kg |

|

Tank Dimensions |

7600*2420*1600mm |

Tank Volume |

23000L |

|

Chassis Parameters |

|||

|

Chassis Model |

BJ1252VMPHE-AB |

Chassis Brand |

FOTON |

|

Overall Dimensions |

9507*2495*2948mm |

Wheel Base |

4300+1300mm |

|

Front/rear wheel track |

1960/1860/1860mm |

Front/rear Suspension |

1532/2375mm |

|

Approach/departure angle |

16/19° |

Maximum Speed |

90km/h |

|

Chassis Manufacture |

Beijing FOTON Daimler Motor Co., Ltd. |

||

|

Cab |

Configuration |

ETX2420 cab(with sleeping berth), allowable 3+2 passengers, ETX interior, air conditioner, seat airbag, with ABS |

|

|

Color |

White、other color is optional |

||

|

Engine |

Model |

CUMMINS ISD245 50 |

|

|

Emission |

Euro 5 |

||

|

Type |

6 cylinders,in-line,water-cooled,turbo inter-cooling,electronic control high pressure common rail, diesel engine |

||

|

Rated Power |

245hp, rated power speed 2500rpm |

||

|

Displacement |

6700ml |

||

|

Max. torque |

950N.m |

||

|

Bore×Stroke |

107*124mm |

||

|

Manufacture |

Beijing FUTON Cummins Engine Co., Ltd. |

||

|

Tire |

Size |

11.00-20 nylon tire |

|

|

Number |

10+1 nos |

||

|

Rear Axle |

10 tons |

||

|

Drive form |

6*4 |

||

|

Suspension |

Multi leaf springs |

||

|

Rated Voltage |

24V, DC |

||

|

Transmissions |

Gear box 8JS1 18T-B, 8 speed forward 1 reverse |

||

|

Steering Device |

Power assisted steering |

||

|

Steer wheel |

Left hand drive |

||

|

If there is a slight change in the chassis parameters above, please take the actual product as the standard |

|||

|

Fuel Tank Structure Parameters |

|||

|

Tank dimensions |

7600*2420*1600mm |

Tank volume |

23000L |

|

Tank material |

Carbon Steel |

Tank Thickness |

5/6 mm |

|

Color and Logo |

Optional |

||

|

Standard Configuration |

Chassis, carbon steel fuel tank, sub frame,oil pump, two aluminum alloy flow valves, tool box, manhole,climbing ladder, fire extinguisher, oil hose. |

||

|

Selective Configuration |

Aluminum alloy fuel tank, flow meter, oiling machine, European standard manhole, pneumatic valve, AlP valve, anti overflow sensor plug, oil and gas recovery system,divided into several bins. |

||

|

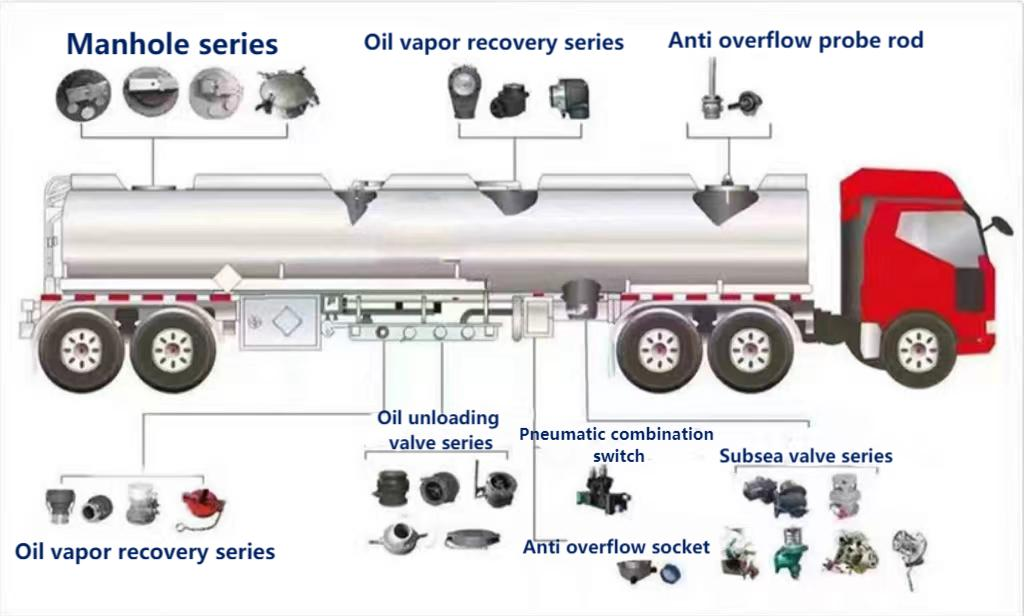

Why is it difficult to get a tanker on the road before 2020? Difficult annual inspection? (Look at the picture to answer the above questions) |

|

|

|

Front disc (disc brake) rear drum brake 1. Front disc (disc brake) rear drum brake: used for emergency braking, to ensure that the vehicle can effectively brake a special device, currently one of the necessary parts on the tank car license; 2. Mainly installed on: the front wheel by two pieces of cast iron clamping a disc brake system, this can be seen; The brake of the rear wheel depends on the expansion of the iron brake skin, which is called the front disc and the rear drum. |

|

|

Anti-spill probe Generally installed next to the irrigation entrance; Purpose: Anti-spill electronic sensor is widely used in all kinds of containers filled with liquid, in order to prevent liquid overflowing leakage in advance alarm device, it is installed on the top of the container tank manhole cover, when the oil level reaches the warning limit, the sensor will automatically alarm off the brake. |

|

|

Submarine valve Generally installed in the tank car tank body outlet; Use: when the external unbalanced force stimulation, can trigger the internal spring to read the rod, so as to cut off the oil pipeline in 5 seconds, to ensure the safety of the interior media, prevent leakage, ignition, explosion: to ensure the safety of the driver friends, goods in the car, outside the car related property and biology! |

|

|

European standard mouth European standard mouth: The left picture shows the aluminum alloy European standard mouth, also known as manhole cover, installed on The top of the oil tank, purpose: with built-in breathing and emergency discharge energy, and can be installed on the manhole cover oil recovery valve, oil hole, anti-overflow probe rod, anti-overflow sensing system in the process of oil loading, when the liquid level reaches the detection position, the sensing system will automatically alarm, so as to stop the oil loading. The inner stomach breathing valve makes the oil tank in the process of oil transport internal pressure to maintain stability, and the external pressure to achieve balance, its dumping to prevent overflow design so that the tank car in the event of an accident to keep sealed, emergency exhaust device in the tank pressure rises sharply in the case, will automatically open, release the tank pressure, so as to prevent accidents, greatly improve the safety of oil transport. |

|

|

Lower the oil valve Generally installed below the side of the tank car; Purpose: Lower oil valve, also known as oil unloading valve, is used for quick oil unloading. The front-end interface meets the American APIRp1004 standard, convenient to connect with the oil discharge hose head. The hydrodynamics design of the internal structure minimizes the internal pressure at high flow rates. The outlet adopts flat bottom structure, no oil leakage when the joint is disassembled, safe and reliable, safe and reliable |

|

|

Oil gas recovery unit Generally installed in the pipe outlet or tank left side Purpose: The oil and gas recovery valve can recover all the oil and gas produced by oil vocalization during loading and unloading to the reservoir tank, avoiding oil and gas leakage and using other oil and gas recovery devices to condense and reuse oil and gas, so as to achieve the purpose of energy saving and environmental protection. |

|

Vehicle Equipment |

|

|

|

Purchase Process |

|

|